1. **Material and Production**

- Made of high-quality seamless pipe cutting, ensuring the product has high strength, pressure resistance and durability.

- The material is usually carbon steel, and the surface is hot-dip galvanized to form a thick zinc layer, providing excellent rust resistance.

2. **Production Process**

- **Cutting**: Seamless pipes are precisely cut to ensure accurate dimensions.

- **Hot-dip galvanizing**: The cut pipe fittings are hot-dip galvanized, and the pipe fittings are immersed in molten zinc liquid to form a uniform and highly adhesive zinc layer, which effectively prevents rust and prolongs service life.

- **Thread Processing**: CNC machine tools process various standard pipe internal threads.

3. **Thread Standard**

- Supports a variety of international standard threads, including:

- **ISO7/1 (BSP)**: International general pipe thread.

- **ISO228**: Non-threaded sealing pipe thread.

- **NPT, NPSC**: American standard pipe thread.

- **DIN2999 (German standard).

- **G (Russian standard)** and other countries' thread standards.

- Specific thread standards can be customized according to customer needs to meet the diverse needs of the global market.

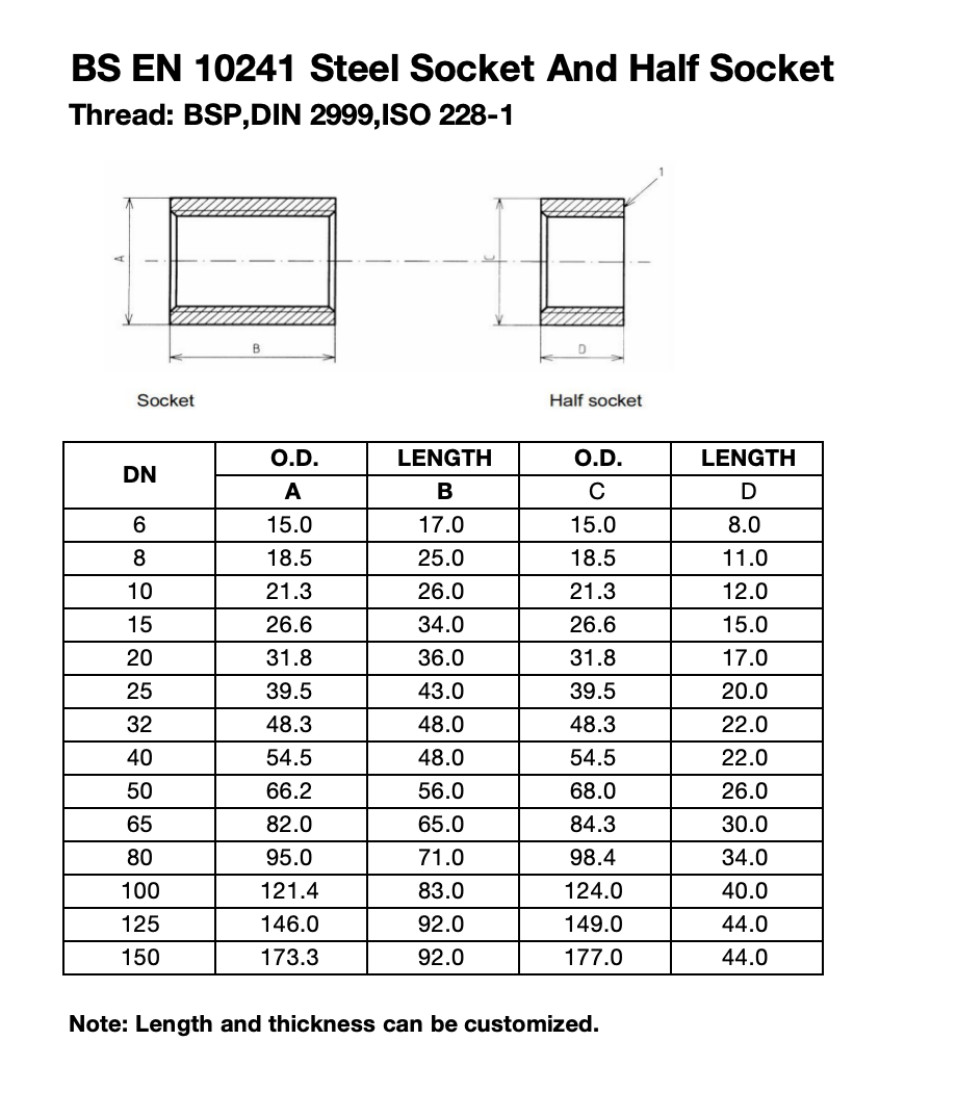

4. **Product standards**

- **BS EN10241**

- **ASTM A865**

- **DIN 2986**

- **GOST 8966**

5. **Specifications and parameters**

- **Specifications**: DN6~DN150 (1/8"~6").

- **Steel pipe**: SCH40, SCH80, SCH160, XS, XXS, etc.

- **Process**: cutting, external treatment, machining, rust prevention, packaging.

6. **Application scenarios**

- Excellent corrosion resistance**: The hot-dip galvanized layer is thick and has strong adhesion, providing long-term anti-rust protection, suitable for construction, municipal engineering, water supply and drainage systems, fire protection systems, and harsh environments requiring corrosion resistance and high sealing.

7. **Customized service**

- Pipe couplings with different specifications, thread standards and thicker hot-dip galvanized zinc layer can be customized according to customer needs to meet the needs of specific application scenarios.