Galvanized pipe couplings are available in three external treatment methods: electrogalvanizing, hot-dip galvanizing, and blackening. Galvanizing can increase the corrosion resistance of steel pipe couplings, provide excellent anti-rust performance and extend service life. All-thread couplings are used to connect various caliber pipe systems for construction, air pumps, water conservancy, fire protection systems, and scenes that require corrosion resistance or various environments.

**Thread standards**

- Support a variety of international standard threads, including:

- **BSP**: International general pipe thread.

- **ISO228**: Non-threaded sealing pipe thread.

- **NPT, NPSC**: American standard pipe thread.

- **DIN2999 (German standard).

- **G (Russian standard)** and other countries' thread standards.

- Specific thread standards can be customized according to customer needs to meet the diverse needs of the global market.

**Product standards**

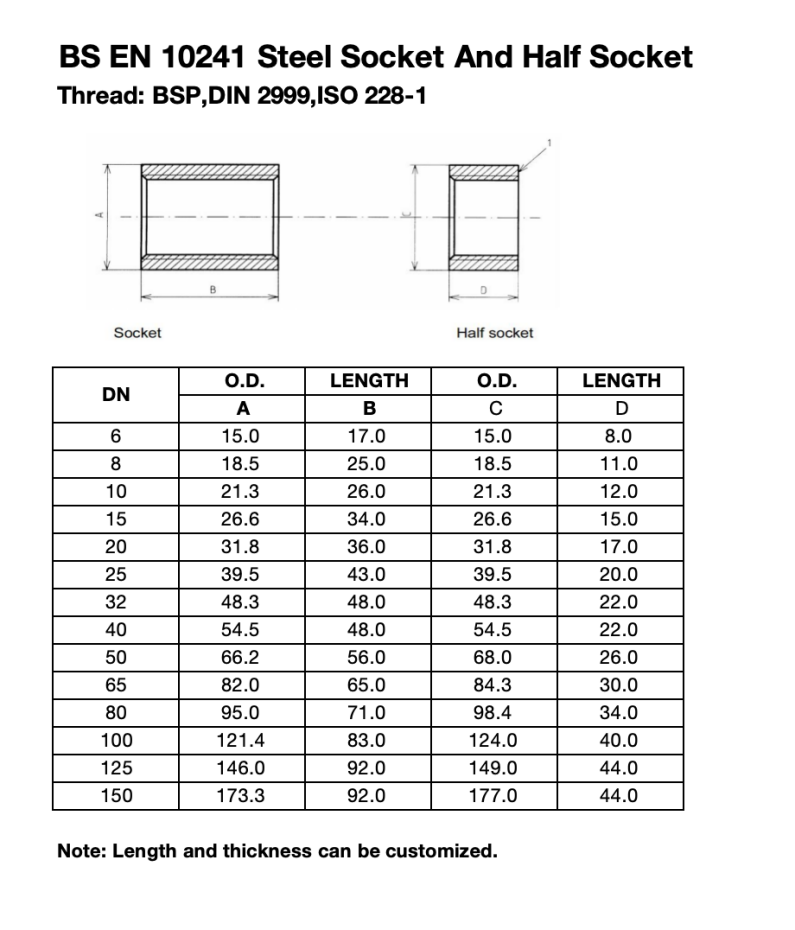

- **BS EN10241**

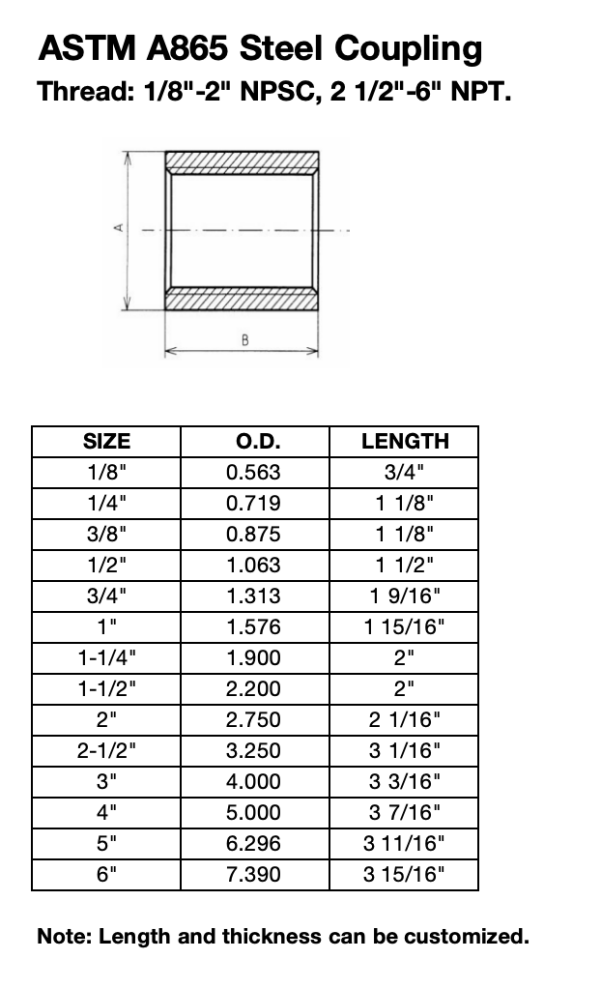

- **ASTM A865**

- **DIN 2986**

- **GOST 8966**

**Specifications**

- **Specifications**: DN6~DN150 (1/8"~6").

- **Steel pipe**: SCH40, SCH80, SCH160, XS, XXS, etc.

- **Process**: cutting, external treatment, machining, rust prevention, packaging.

**Packing requirements**

Conventional export standards for carton and wooden pallet.

**Customized service**

- Pipe coupling with different specifications, application standards and various external surface treatments can be customized according to customer needs to meet the needs of specific application scenarios.