ASTM A865 carbon steel pipe couplings are designed for connecting pipeline equipment in the United States and are suitable for threaded connection requirements of American standards.

1. **Material and production**

- Made of high-quality seamless pipe cutting and processing to ensure high strength and durability of the product.

- The material of the seamless pipe can be selected according to demand, such as carbon steel ASTM A53, stainless steel ASTM A312, etc., to meet the corrosion resistance and pressure resistance requirements in different environments.

2. **Surface treatment**

- During the production process, carbon steel pipes are first electro-galvanized or sandblasted, and stainless steel pipes are first sandblasted or polished to increase the corrosion resistance of steel pipe joints and remove surface impurities and increase beauty to provide better anti-corrosion and anti-rust capabilities.

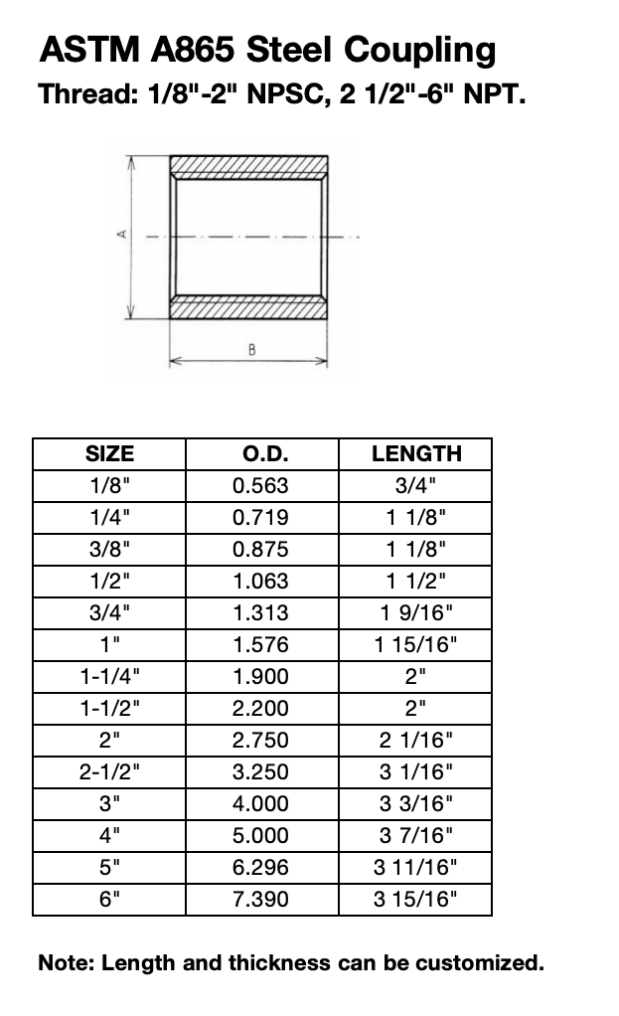

3. **Thread standard**

- **NPT, NPSC, NPSM**: American standard pipe threads.

- Specific thread standards can be customized according to customer needs to meet the diverse needs of the global market.

4. **Product Standard**

- **ASTM A865**

- **API 5L**

5. **Specifications and Parameters**

- **Specifications**: 1/8"~8"

- **Steel Pipe**: SCH40, SCH80, SCH160, XS, XXS, etc.

- **Process**: cutting, external treatment, machining, rust prevention, packaging.

6. **Application Scenarios**

- Widely used in industries such as petroleum, natural gas, chemical industry, and construction for connecting pipelines or welding equipment.

- Suitable for high pressure, high temperature environments, and occasions requiring high sealing.

- Pipe couplings of different materials, specifications, and thread standards can be customized according to customer needs, supporting a variety of international standards, and are ideal for pipeline connections and welding equipment.

Product parameter: